director's brief

By Byron Wolff

Thanks for taking the time to check in on our Autumn newsletter. In December, we were hoping for the predicted above average summer rainfall for the north to materialise. What a mixed bag of surprises Australia actually received?! Despite continual weather challenges the industry has generally remained positive and it has been encouraging to see continued innovation.

In 2014 Thompson Longhorn pioneered the use of drones for the purpose of collecting existing cattle yard site information and then utilising the data to redesigning and improving safety, welfare and efficiency. Since Christmas, two separate and non-related projects have kicked off that may offer break throughs to monitoring livestock behaviour and livestock feed optimisation, one utilising drones.

Along side these innovative studies, recent research has identified that further opportunities can be realised in the feedlot sector by increasing automation levels (click here to read more).

Last year we witnessed several red meat processing automation projects announced, which show plenty of promise (click here to read more).

It is hard to explain how exciting it is to be involved in such a progressive and positive industry, despite the continual challenges. There is little doubt that Australia punches well above it's weight on the global stage and in many cases leads the world in livestock management technology.

Autodrafting Cattle

By Kelly Keong

'Auto drafting' is a term that has become much more commonly used within our segment of the industry in recent years, but what does the term actually mean? Most cattle producers have heard of the concept, but individual interpretations can be quite varied. In more recent years we have seen a maturing of this market segment, and as a result it is not surprising that some clarification of what automated processes are now available to 'auto-draft' animals is past due.

For almost 20 years, Thompson Longhorn has specialised in building automated cattle handling equipment. During this time, we have delivered widely varying degrees of cattle yard automation.

It could be argued that automating a gate(s) in a lane draft or pound yard with a pneumatic (or less commonly used hydraulic) cylinder produces a basic level of 'auto-draft'. Whilst these innovations offer great improvements to operator safety and animal welfare, this mechanisation is not an 'auto-draft'. This is a fairly common misunderstanding.

The second misunderstanding is that your new scale head, RFID reader or field computer running herd management software can somehow take physical control of your mechanised gates - aka 'auto-drafting'. These important and intelligent management tools are definitely a critical part of the process but have no ability to directly make any gate move. What these devices do extremely well, is combine real time data collection (weight, RFID, historical animal information) with user defined sorting rules to give the operator accurate answers, at a speed and level of accuracy that is not humanly possible.

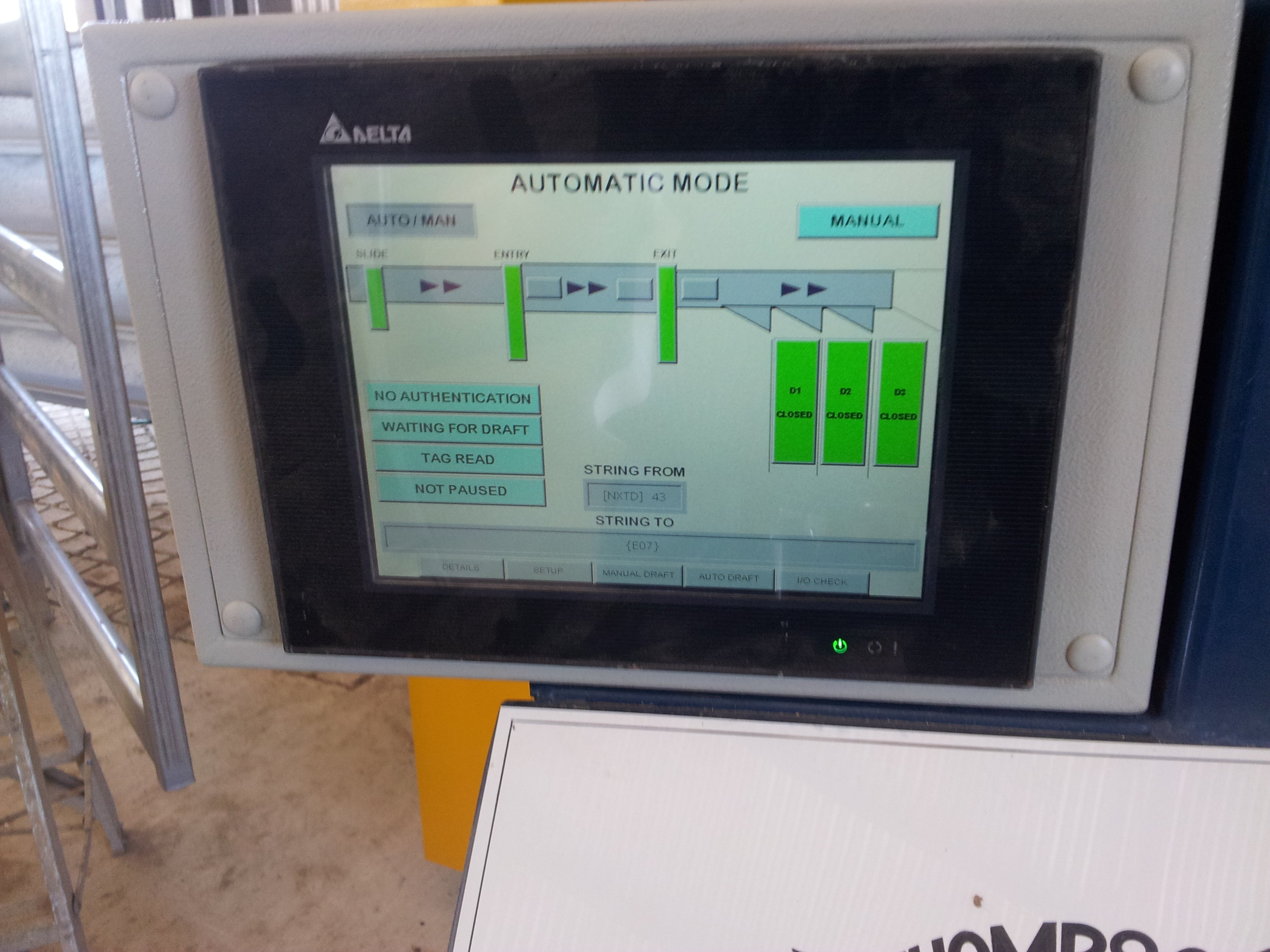

An 'auto-drafter' is the missing link that ties your mechanised gates and smart crush side data processor together by listening to the code coming from a scale head or PC and being able to then take control and make gates move.

In summary, there are three important parts required to create a complete system:

- Mechanisation of the hardware: actuators or powered cylinders connected to the drafting gates and perhaps the entry and exit gates to the RFID scanner/weigh box, and the ability to control these gates electronically.

- The automation of the draft choice: a computer-generated draft choice based on live and pre-programmed criteria. Typically, this is performed by a smart scale indicator with draft capability, PC based herd management software or an intelligent RFID reader (as in a drafter used to separate non-reading animals for re-tagging).

- 'Auto-draft' controller - realising the value of the system: once the draft choice has been made in the scale indicator or PC, the computer code needs to be translated and then used to generate electronic signals (usually 24-volt DC) that can be sent to gate control solenoids. This device has varying levels of intelligence available and can sequence events to ensure that other draft gates are closed before opening a new gate or that the draft gate is open before releasing the animals from the scanner/weigh box. Autonomous drafting (look mum, no humans!) can also be achieved via adding animal location sensors to the system so that the auto-draft controller knows where the livestock are within the system at all times.

So, when is some form of cattle yard automation warranted? One might think that business (herd) size would be a determining factor to work out who does and does not adopt these newer technologies - not true. We have instead witnessed a trend of adoption from organisations and individuals who have taken a longer-term view of their businesses and have made deliberate steps towards improving operator safety, animal welfare and reducing operating costs (labour saving). Time and again it has been proven that simply starting by automating drafter gates, is well worth the the expense for most cattle producers.

At the other end of the scale, most commercial feedlot operations use livestock management software and require drafting animals on recorded historical data (like veterinarian withholding periods, home pens etc.). RFID makes this possible but the sequencing of various pieces of automated equipment, scanners and sensors using an auto draft controller, makes true auto drafting a reality.

in development: hydraulic tipping restrainer

By Heidi Green

Here at Thompson Longhorn we love to design innovative equipment to make your work life easier, safer and more efficient. Often this process starts with a seemingly simple question like, "Can I have a restrainer that is also a tipping table?" The simple answer is yes you can. Another question worth asking is "Why?" you would want a Tipping Restrainer. Two main reasons; you only need to catch your cattle once, and you only need to maintain one piece of equipment.

Such a versatile piece of equipment is an interesting challenge in many ways, especially keeping all the features of a restrainer, when upright, and sufficient hoof access when tipped. Of course, we also want to ensure that we provide easy to use, safe solutions for both workers and cattle.

Our design team is working on a hydraulically powered Tipping Restrainer, to reduce the heavy lifting, and offer features like powered leg grabs. Which are designed to make the process of hoof trimming as easy and safe as possible. The idea is simple, encourage each leg to the nearest grab, push a button, and the hydraulics do the rest, holding each leg in place until you are finished and release them.

We have kept a dual squeeze system, to keep your cattle comfortable and safely restrained, both when tipped and upright. A dual squeeze system also means that you can raise and lower tipped animals, to a safe and convenient height for your workers. Both squeezes are shaped wider at the belly of your cattle, to better hold each animal from shifting, especially when tipped. Which also helps animals to be tipped back onto their feet.

Very soon we will be enjoying the next most exciting phase - physically building a prototype and testing it out.

have you read our free ebook?

Our free eBook outlines some of the perennial challenges and questions that you may face when you are looking to invest in new equipment or yards. We understand that this can be a confusing and complicated process, our eBook shows you how we can make the process easier for you.

Get your free copy here

come and see us at our factory

288 Inverramsay Road, 75 kilometres from Toowoomba

We welcome you to visit use to see our automated trade display and our robotic welding facility. Our factory is only a 50 minute drive from Toowoomba. Simply turn east just south of Allora at the Goomburra turnoff and 12.5km later you will be at Thompson Longhorn.

An appointment is necessary for factory tours. To book an appointment please call us on (07) 4666 6174.

have you checked out our facebook page?

Click here to visit our Facebook page

288 Inverramsay Road, Goomburra, Qld, 4362,

Ph: (07) 4666 6174, Fax: (07) 4666 6242,

Email: sales@thompsonlonghorn.com.au

www.thompsonlonghorn.com.au

Opening hours: 8.00am until 5.00pm Monday to Friday